TRANSMISSION

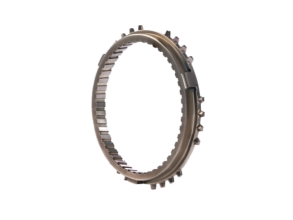

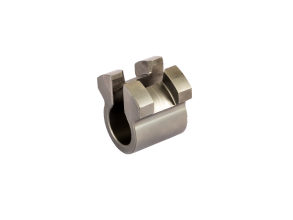

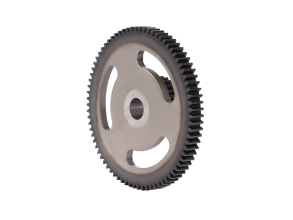

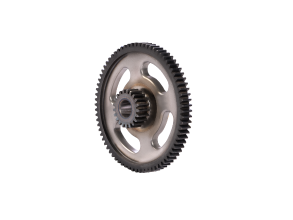

Sintercom India Ltd. manufactures a broad range of components for transmissions for both 2-wheeler and 4-wheeler automobile platforms. Our product portfolio includes synchroniser hubs, dog rings and drive-train gears.

Through the technology and engineering prowess, the company is able to produce high precision sintered components for transmissions to replace high strength forged components. These components provide superior value for leading automotive customers through better performance and reduction in weight of drivetrain.

PRODUCTS

Finger Interlock

Hub High Speed

Hub Synchro 5th

Hub Synchro Reverse

Intermediate Gear 2-3

Intermediate Gear 4-5

Shift Finger 4th Rail